Table of Contents

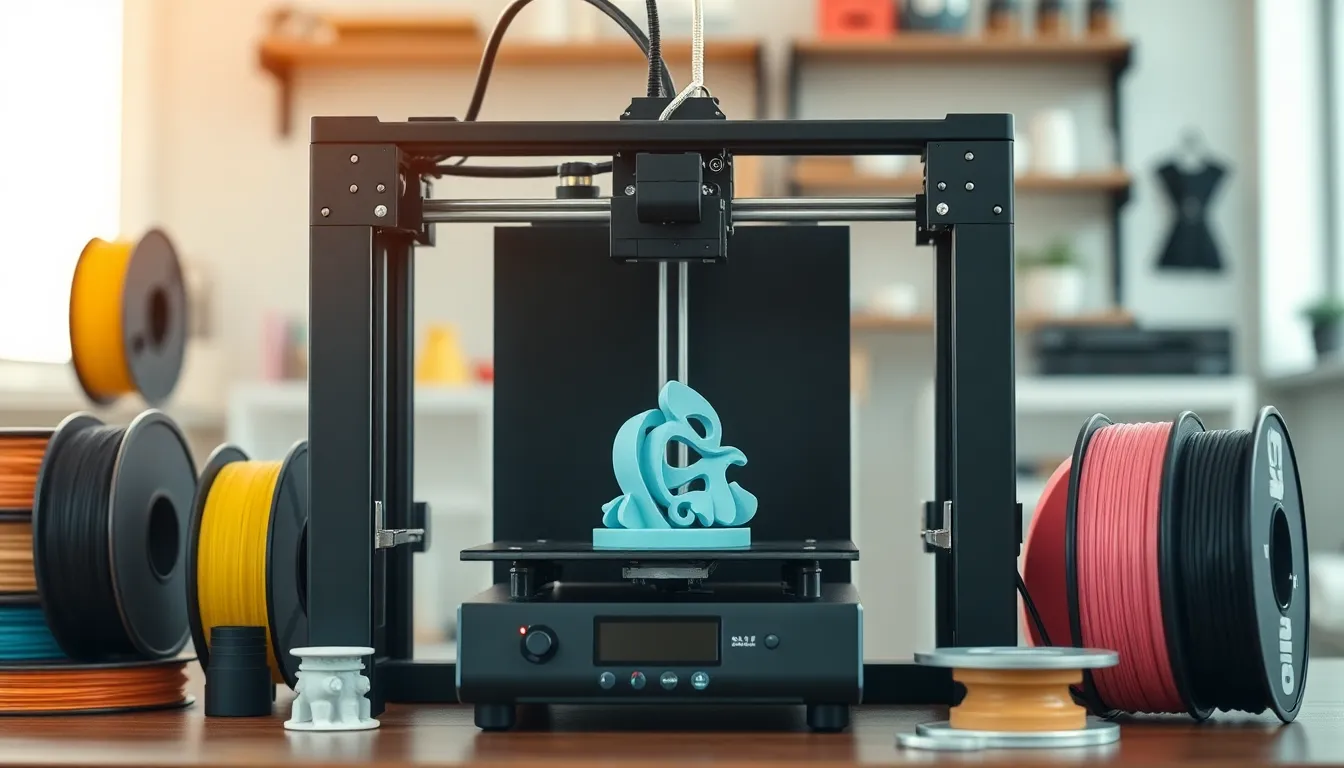

ToggleImagine a world where creativity knows no bounds, where your wildest design dreams can leap off the screen and into reality. Enter the dual extruder 3D printer, the superhero of the printing world. With its ability to handle two filaments at once, it’s like having a sidekick that doubles your production power and unleashes a rainbow of colors and materials.

Overview of Dual Extruder 3D Printers

Dual extruder 3D printers represent a significant advancement in additive manufacturing. These printers utilize two different filaments simultaneously, allowing for more complex designs. Users can create parts with multiple colors or materials in a single print job, enhancing functionality.

Flexibility is a key feature of dual extruder printers. They accommodate various filament types, including PLA, ABS, and specialty materials like nylon or TPU. This opens up possibilities for printing multi-material objects such as functional prototypes or intricate artistic designs.

Many dual extruder printers offer independent dual extruder systems. Such systems allow each extruder to operate independently, minimizing the risks of clogs and print failures. The combined use of different materials can improve the mechanical properties of prints, such as increased strength or flexibility.

Design complexity also increases with dual extruder technology. Users can print support structures with a soluble material, enabling easier removal without damaging the main model. Enhanced detail in prints comes from the ability to utilize more than one filament, as each part can be designed with its own material properties.

Cost typically influences the decision to purchase a dual extruder printer. Prices vary depending on the brand and features, with options available for different budgets. Evaluating specifications such as print volume and resolution ensures the right choice for individual needs.

Overall, dual extruder 3D printers offer a powerful tool for diverse applications in the 3D printing landscape.

Key Features of Dual Extruder 3D Printers

Dual extruder 3D printers boast essential features that enhance their functionality and versatility.

Print Quality

Print quality benefits significantly from dual extruder technology. Users can achieve detailed layers with precise color blending and smooth finishes. Advanced calibration options improve accuracy by fine-tuning each extruder’s performance. Enhanced control over material flow results in minimal stringing and improved layer adhesion. Prints often exhibit superior strength and durability, making them ideal for prototypes and final products. Models equipped with independent dual extruders minimize the risk of extrusion issues, ensuring consistent output and higher overall quality.

Material Compatibility

Material compatibility offers a wide array of options for dual extruder 3D printers. Users can utilize multiple filament types simultaneously for advanced applications. Common materials include PLA, ABS, and PETG, with specialty filaments like nylon or TPU enhancing creativity. The ability to print with soluble materials for support structures adds significant value, as they dissolve easily post-printing. Compatibility with various materials allows the creation of multi-material objects, which expands the possibilities for design and functionality. Many printers accommodate both standard and flexible filaments, ensuring users can explore innovative solutions.

Advantages of Using Dual Extruder 3D Printers

Dual extruder 3D printers offer a range of advantages, significantly enhancing the 3D printing experience.

Multi-Material Printing

Multi-material printing stands out as one of the primary advantages. Users can combine two different filaments in a single print, enabling the creation of complex objects with varied textures and colors. This capability allows for innovative designs that involve flexible components alongside rigid parts. Artisans often use dual extruders to produce multi-colored prints without tedious post-processing tasks. Filament compatibility broadens the range of materials, including specialty blends suitable for unique projects. Furthermore, the option to implement soluble support materials streamlines the printing process, providing easy removal without interfering with the final product.

Improved Efficiency

Improved efficiency comes from the streamlined workflow associated with dual extruder systems. The ability to print with two materials simultaneously reduces the overall printing time compared to traditional single-extruder methods. Features such as independent movement of extruders minimize clogs and ensure smooth operation. Designers often experience fewer failed prints due to the reliable dual system, which cuts down on material waste. Enhanced print speeds, combined with minimal downtime for changing filaments, lead to increased productivity. Many users report enjoying better results in a shorter time frame, allowing for quicker iterations and faster project completion.

Challenges and Considerations

Dual extruder 3D printers offer several advantages, but they also present specific challenges that users must navigate. Proper calibration and setup play crucial roles in achieving successful prints.

Calibration and Setup

Calibration involves adjusting the printer’s settings to ensure accurate filament alignment and optimal layer adhesion. Users need to spend time fine-tuning the extrusion temperatures and flow rates for each filament type. Maintaining proper distance between the nozzles prevents interference during printing. It’s essential to follow specific steps when setting up a dual extruder system to reduce issues like clogging or misalignment. Without thorough calibration, print quality may diminish, leading to wasted materials and time.

Maintenance and Cost

Regular maintenance ensures the longevity and reliability of dual extruder 3D printers. Users typically face increased costs related to the purchase of high-quality filaments and replacement parts for two extruders. Frequent cleaning of the nozzles and the filament paths becomes necessary to avoid clogs. Although these printers provide enhanced capabilities, they present a more complex setup compared to single extruder models. Budgeting for both initial investment and ongoing maintenance plays a vital role in the overall operational efficiency of dual extruder systems.

Dual extruder 3D printers represent a significant advancement in the 3D printing world. Their ability to print with multiple materials opens up a realm of creative possibilities for designers and engineers alike. By combining different filaments users can achieve stunning visual effects and functional prototypes that were once difficult to create.

While the benefits are substantial the challenges associated with calibration and maintenance shouldn’t be overlooked. Users must invest time and resources to ensure optimal performance. Despite these considerations the advantages of improved print quality and efficiency make dual extruder printers a worthwhile investment for those looking to elevate their 3D printing projects. As technology continues to evolve these printers will undoubtedly play a crucial role in shaping the future of additive manufacturing.