Table of Contents

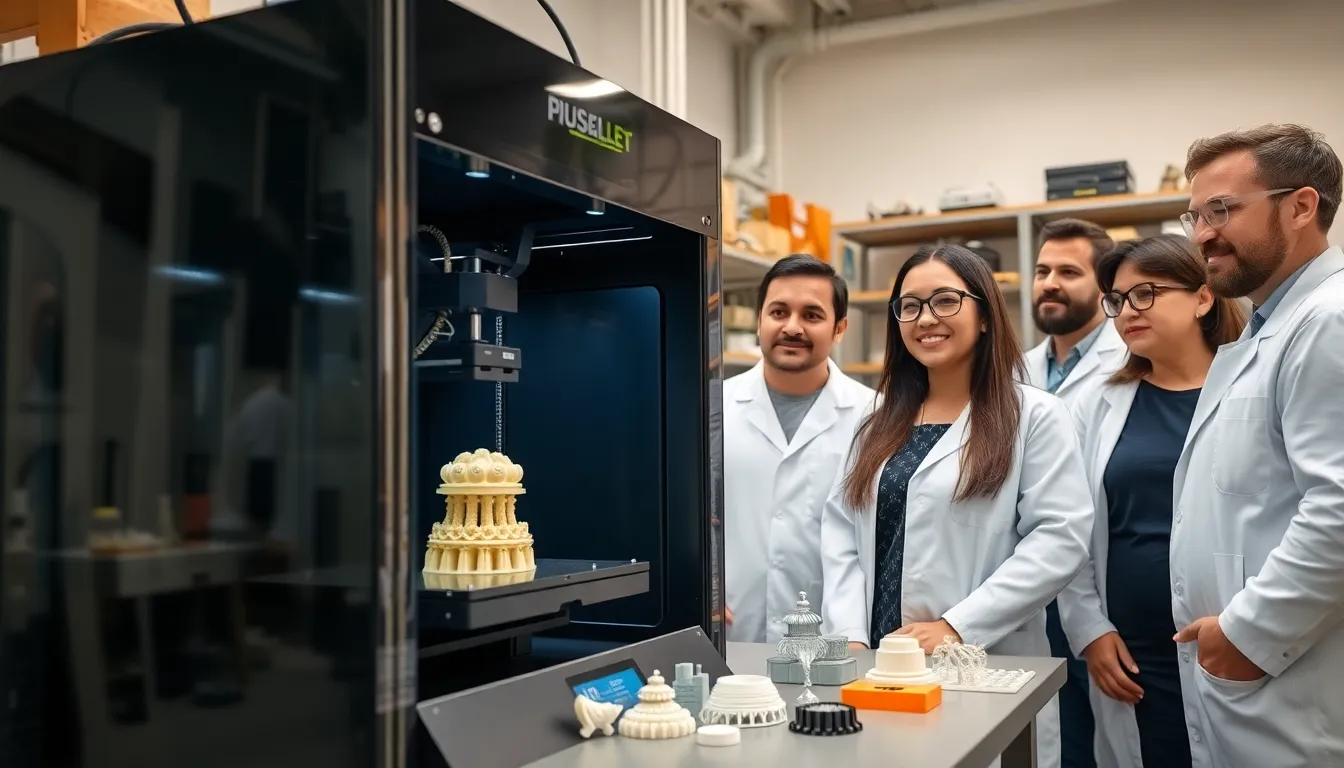

ToggleIn a world where everything seems to be going digital, 3D printing is the superhero manufacturing never knew it needed. Forget about the days of waiting weeks for parts to arrive; with 3D printing, manufacturers can whip up prototypes faster than you can say “layer by layer.” This technology isn’t just a fad; it’s revolutionizing how products are made, one plastic filament at a time.

Imagine a factory floor where creativity runs wild and mistakes can be fixed with a simple press of a button. That’s the magic of 3D printing. It’s not just about making things; it’s about making things better, cheaper, and with a sprinkle of fun. As industries embrace this game-changer, the future of manufacturing looks brighter than ever, and it’s all thanks to a little bit of plastic and a whole lot of innovation.

Overview of 3D Printing in Manufacturing Industry

3D printing, also known as additive manufacturing, revolutionizes production methods across various sectors. The technology enables manufacturers to create complex geometries that traditional methods struggle to achieve. Cost savings are significant, particularly in tooling and material waste, allowing for more efficient resource management.

Rapid prototyping stands out as one of the key benefits of 3D printing. Manufacturers can produce functional prototypes within days, streamlining design processes and expediting product development. Speed translates to a more agile response to market demands, giving businesses a competitive edge.

Customization represents another hallmark of 3D printing in manufacturing. Companies can tailor products to meet specific customer needs without incurring substantial costs. This flexibility supports a shift towards mass customization, where individualized products maintain affordability.

Quality assurance plays an essential role in the adoption of 3D printing technologies. Manufacturers continuously refine processes to enhance the mechanical properties of printed parts. Reliability in production benefits industries such as aerospace and medical, where precise specifications are paramount.

Increased innovation characterizes the landscape of manufacturing thanks to 3D printing. Companies explore novel materials and techniques, fostering a culture of creativity and experimentation. Enhanced collaboration between designers and engineers leads to breakthroughs in product design and functionality.

Integration of 3D printing with digital technologies further strengthens its application in manufacturing. Technologies like IoT and AI offer valuable data insights, facilitating smarter production methods. As industries embrace these trends, 3D printing emerges as a pivotal component in the future of manufacturing.

Key Benefits of 3D Printing

3D printing offers numerous advantages that significantly enhance manufacturing processes. Notably, its cost efficiency and design flexibility play key roles in its adoption across industries.

Cost Efficiency

Cost efficiency stands out as a major benefit of 3D printing. It minimizes the investment in tooling and reduces material waste, which lowers overall production costs. Manufacturers avoid lengthy setup times associated with traditional methods, leading to quicker turnaround on orders. Additionally, 3D printing allows for the on-demand production of parts, which eliminates the need for large inventories. Significant savings on labor and materials contribute to overall profitability in the long run. Efficient resource utilization and a streamlined production process enhance financial viability for businesses adopting this technology.

Design Flexibility

Design flexibility becomes another crucial advantage of 3D printing. Complex geometries and intricate structures that traditional manufacturing struggles to produce can be created with ease. This technology fosters innovation, enabling designers to explore new concepts without the constraints of conventional methods. Customization options empower companies to cater to specific consumer preferences, which enhances customer satisfaction. Rapid prototyping allows for quick adjustments, making iterative design processes more efficient. Overall, 3D printing facilitates a level of design freedom that traditional techniques cannot match, encouraging creativity and enhancing product offerings.

Applications of 3D Printing in Manufacturing

3D printing finds numerous applications across the manufacturing landscape. Its capacity for rapid prototyping and customization fundamentally reshapes how products are developed and designed.

Prototyping and Product Development

Prototyping becomes faster through 3D printing technologies. Manufacturers can create functional prototypes in days rather than weeks, significantly reducing product development cycles. This speed enables companies to test designs more efficiently, identify flaws, and enhance features. Iterative design processes thrive in this environment, where adjustments happen quickly based on feedback. For instance, in the automotive sector, firms leverage rapid prototyping to test components before mass production. Effective collaboration between engineering and design teams also enhances innovation, resulting in superior products tailored to market demands.

Customization and Personalization

Customization emerges as a critical advantage of 3D printing. Manufacturers can adapt designs to meet specific customer preferences without incurring prohibitive costs. This process allows for on-demand production of unique items, making it feasible to deliver personalized products at scale. For example, the medical industry benefits immensely by producing prosthetics tailored to individual patients, improving fit and comfort. Retailers also utilize this technology to offer bespoke consumer goods, enhancing customer satisfaction. Personalization not only drives sales but also fosters customer loyalty, showcasing the versatility and relevance of 3D printing in today’s market.

Challenges Facing 3D Printing in Manufacturing

Manufacturing with 3D printing comes with its own set of challenges. These obstacles can hinder the technology’s wider adoption and effectiveness.

Material Limitations

Material options for 3D printing often present challenges. Many companies rely on a limited range of materials, which can restrict design possibilities. Additionally, some materials lack the mechanical properties that certain applications demand, particularly in high-stress environments. Finding alternatives can require extensive research and development efforts. Moreover, the costs associated with advanced materials often increase manufacturing expenses. Companies aiming to leverage 3D printing must carefully consider material selection to ensure performance standards are met while remaining cost-effective.

Regulatory Compliance

Ensuring regulatory compliance can be daunting in 3D printing. Different industries have stringent standards that manufacturers must adhere to for safety and quality assurance. Aerospace and medical sectors often impose rigorous testing and certifications, making compliance a complex process. Navigating the intricacies of these regulations requires a thorough understanding of both the technology and industry expectations. Furthermore, the evolving nature of 3D printing means that regulations can shift, making it essential for manufacturers to stay updated on compliance requirements. A proactive approach helps organizations mitigate risks associated with non-compliance.

Future Trends in 3D Printing

Advancements in 3D printing technology continue to shape the manufacturing landscape. Improved printing speeds and enhanced resolution allow for more detailed and accurate production. Innovations in materials, such as metal and bio-printing, expand application possibilities, enabling industries like aerospace and healthcare to thrive. Enhanced software tools streamline design processes, allowing seamless integration of complex geometries. Implementation of artificial intelligence in print processes optimizes production efficiency and quality control, reducing waste. Companies embracing these advancements position themselves at the forefront of their industries.

Sustainable practices increasingly define the future of 3D printing. Reducing material waste stands as a key benefit, as additive manufacturing uses only what’s necessary for production. Renewable materials and biodegradable options gain traction, aligning with environmental goals. Energy-efficient printing methods also contribute, resulting in lower carbon footprints compared to traditional manufacturing methods. Collaboration among manufacturers to develop recycling programs improves resource utilization and minimizes environmental impact. Embracing sustainability enhances brand reputation while responding to consumer demand for eco-friendly products.

3D printing is reshaping the manufacturing landscape with its innovative capabilities. As industries embrace this technology, they unlock new levels of efficiency and creativity. The ability to produce customized products on demand not only meets consumer preferences but also drives customer loyalty.

While challenges like material limitations and regulatory compliance remain, ongoing advancements promise to address these hurdles. The focus on sustainability and resource efficiency further positions 3D printing as a critical player in the future of manufacturing. As manufacturers continue to explore its potential, 3D printing will undoubtedly play a pivotal role in shaping the industry’s trajectory for years to come.